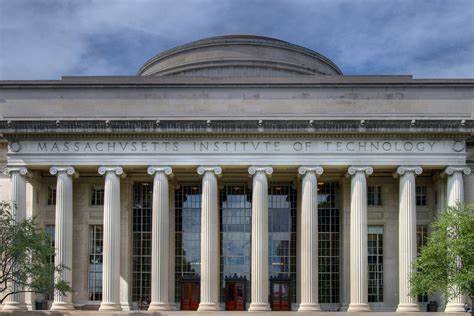

In the quest for clean and sustainable energy, nuclear power stands as a beacon, promising substantial reductions in greenhouse gas emissions. However, the persistent challenge of soaring construction costs has hindered the growth of nuclear capacity in the United States for decades. Despite optimistic projections and expectations that experience would lead to cost reductions, the reality has been quite the opposite. A team of researchers from MIT has delved into the intricacies of nuclear power plant construction, uncovering the reasons why costs consistently exceed projections.

Estimates for the capital cost of a new nuclear power plant in the U.S. ranged from $6 billion to $9 billion per gigawatt (GW) of electrical capacity. However, these figures are approximate, and costs can vary significantly based on the specific circumstances of each project. Some recent estimates have suggested even higher costs. Advances in nuclear technology, such as small modular reactors (SMRs), are being explored as potential solutions to reduce costs and construction times. SMRs have the advantage of modular construction, which may offer more predictable costs and schedules compared to traditional large-scale reactors.

The significant upfront costs of nuclear power plants include a range of expenses associated with planning, design, licensing, construction, and initial operational activities. Keep in mind that these costs can vary based on factors such as the reactor type, site conditions, regulatory environment, and local labor and material costs. See below table for a list of costs:

The Illusive Learning Curve:

Traditionally, the assumption has been that experience with a particular technology would drive down costs, a concept often expressed through the “learning rate” — the percentage cost reduction associated with a doubling of cumulative production. However, empirical evidence within the nuclear power sector contradicts this assumption. The MIT team, led by Associate Professor Jessika E. Trancik, scrutinized data from 107 nuclear plants across the United States, spanning five decades. Surprisingly, their findings revealed a negative learning rate, indicating that instead of decreasing, costs have consistently risen.

Video: Estimating the Costs of Nuclear Plant Construction is Difficult

Beyond Safety Regulations:

While stricter safety regulations have often been cited as a primary culprit for escalating costs, the MIT researchers sought a more nuanced understanding. By examining cost data from the U.S. Department of Energy’s Energy Economic Data Base between 1976 and 1987, they dissected the contributors to overall cost increases, categorizing them into direct and indirect costs. The results indicated that a staggering 72% of the cost escalation during that period was due to indirect costs, encompassing engineering services, on-site job supervision, and temporary construction facilities.

Analyzing the Components:

To pinpoint the elements responsible for the indirect cost surge, the researchers scrutinized specific plant components. The nuclear steam supply system, the turbine generator, and the containment building emerged as major influencers. These components not only contributed significantly to indirect costs but also played a crucial role in the escalation of direct costs.

A Case Study: The Containment Building:

For a deeper understanding, the researchers conducted a case study focusing on the containment building — a critical and costly component designed to prevent the escape of radioactive materials. The study, spanning from 1976 to 2017, revealed a doubling of the containment building’s cost, with 80% of the increase attributed to changes in wall thickness and material deployment rates. Importantly, the study highlighted the impact of declining on-site labor productivity, a factor more pronounced in the nuclear construction industry compared to the broader construction sector.

Prospective Strategies for Cost Reduction:

Armed with insights into historical cost escalations, the researchers explored prospective strategies to mitigate future construction costs. Three scenarios were analyzed: a broad cost improvement approach, an emphasis on on-site productivity through advanced manufacturing, and the utilization of advanced construction materials. While each scenario presented potential cost reductions, the challenges persisted.

Implications and Encouragements:

The analyses conducted by the MIT team not only shed light on the historical challenges of nuclear plant construction but also provide a pathway for future exploration. The research emphasizes the need for technology development to reduce material usage and automate construction processes. While challenges related to safety standards and large-scale dimensions persist, the findings offer valuable insights for engineers, developers, and investors.

Conclusion:

Unlocking the puzzle of nuclear plant construction costs is critical for realizing the full potential of nuclear power in the transition to a low-carbon energy future. The MIT researchers’ innovative approach, grounded in data analysis and case studies, provides a roadmap for addressing the persistent issue of cost overruns. By guiding research and development efforts toward targeted areas, the nuclear industry can aspire to not only meet energy needs sustainably but also navigate the complex landscape of regulatory requirements and construction challenges.